Collection: Zyglo Fluorescent Penetrant materials

Magnaflux Zyglo Fluorescent Penetrant is a professional-grade nondestructive testing (NDT) solution for liquid penetrant inspection (LPI). Magnaflux offers a comprehensive range of liquid penetrant testing products designed for nondestructive testing (NDT). The Zyglo line includes multiple sensitivity levels (Level 2, 3, and 4) and testing methods, including water washable and post-emulsifiable formulations. QPL SAE AMS 2644 and Pratt & Whitney approved, these penetrants detect surface discontinuities in critical components across aerospace, automotive, and manufacturing industries. Zyglo penetrants provide reliable crack detection, ensuring component safety and quality compliance with industry standards like ASTM E1417.

-

Magnaflux Zyglo ZE-4E Emulsifier

Regular price From $621.00Regular priceUnit price / per -

Magnaflux Zyglo ZL-150 Penetrant - Level 2

Regular price $5,045.00Regular priceUnit price / per -

Magnaflux Zyglo ZL-15B Penetrant - Level 1/2

Regular price From $535.00Regular priceUnit price / per -

Magnaflux Zyglo ZL-19 Penetrant - Level 1

Regular price From $579.00Regular priceUnit price / per -

Magnaflux Zyglo ZL-27A Penetrant - Level 3

Regular price From $54.95Regular priceUnit price / per -

Magnaflux Zyglo ZL-2C Penetrant - Level 2

Regular price From $706.00Regular priceUnit price / per -

Magnaflux Zyglo ZL-37 Penetrant - Level 4

Regular price From $58.95Regular priceUnit price / per -

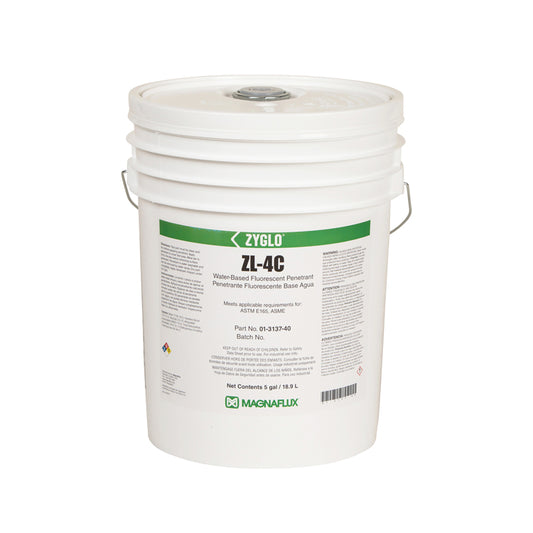

Magnaflux Zyglo ZL-4C Penetrant

Regular price From $841.00Regular priceUnit price / per -

Magnaflux Zyglo ZL-56 Penetrant - Level 4

Regular price From $1,651.00Regular priceUnit price / per -

Magnaflux Zyglo ZL-60D Penetrant - Level 2

Regular price From $51.95Regular priceUnit price / per -

Magnaflux Zyglo ZL-67 Penetrant - Level 3

Regular price From $848.00Regular priceUnit price / per -

Magnaflux Zyglo ZP-14A Developer

Regular price From $616.00Regular priceUnit price / per -

Magnaflux Zyglo ZP-5B Developer - 25 lb. Pail

Regular price $794.00Regular priceUnit price / per -

Magnaflux Zyglo ZP-9F Developer

Regular price From $33.95Regular priceUnit price / per -

Magnaflux Zyglo ZR-10E Hydrophilic Emulsifier and Remover

Regular price From $597.00Regular priceUnit price / per -

ZL-405 Water-Based Fluorescent Penetrant

Regular price $2,794.00Regular priceUnit price / per -

ZL-425 Water-Based Fluorescent Penetrant

Regular price $4,384.00Regular priceUnit price / per -

ZL-440 Water-Based Fluorescent Penetrant

Regular price $5,282.00Regular priceUnit price / per

Introduction to Zyglo Products

Zyglo is Magnaflux's premium fluorescent penetrant testing product line, designed for liquid penetrant inspection (LPI) applications. These products are formulated with high-quality fluorescing dyes and solvents to provide superior detection of extremely small surface discontinuities in virtually any nonporous material.

Product Categories

1. Water Washable Fluorescent Penetrants (Method A)

Best For: General-purpose inspections, high-volume production, ease of use

ZL-150 (Level 2)

- Sensitivity: Level 2

- Applications: General manufacturing, automotive parts

- Standards: QPL SAE AMS 2644 approved

- Method: Type 1, Method A and Method C

ZL-15B (Level 1/2)

- Sensitivity: Level 1/2

- Applications: Moderate sensitivity requirements

- Standards: QPL SAE AMS 2644 approved

- Method: Type 1, Method A and Method C

ZL-19 (Level 1)

- Sensitivity: Level 1

- Applications: Basic inspections, semi-porous surfaces, protective armor

- Standards: QPL SAE AMS 2644 approved

- Method: Type 1, Method A and Method C

- Special Features: Effective on challenging surfaces

ZL-56 (Level 4)

- Sensitivity: Level 4 (Ultra-high sensitivity)

- Applications: Critical safety components, aerospace applications

- Standards: QPL SAE AMS 2644 approved

- Method: Type 1, Method A and Method C

ZL-60D (Level 2)

- Sensitivity: Level 2

- Applications: Aerospace components, precision manufacturing

- Standards: QPL SAE AMS 2644 and Pratt & Whitney approved

- Method: Type 1, Method A and Method C

ZL-67 (Level 3)

- Sensitivity: Level 3

- Applications: High-sensitivity aerospace testing

- Standards: QPL SAE AMS 2644 and Pratt & Whitney approved

- Method: Type 1, Method A and Method C

2. Post-Emulsifiable Fluorescent Penetrants (Method B)

Best For: Maximum process control, critical applications, enhanced sensitivity

ZL-27A (Level 3)

- Sensitivity: Level 3

- Applications: Safety-critical aerospace testing, maximum process control

- Standards: QPL SAE AMS 2644 and Pratt & Whitney approved

- Method: Method B, Method C, and Method D

- Special Features: High-sensitivity, requires emulsifier for removal

ZL-2C (Level 2)

- Sensitivity: Level 2

- Applications: General post-emulsifiable applications

- Standards: QPL SAE AMS 2644 and Pratt & Whitney approved

- Method: Method B, Method C, and Method D

ZL-37 (Level 4)

- Sensitivity: Level 4 (Ultra-high sensitivity)

- Applications: Most critical inspections requiring maximum sensitivity

- Standards: QPL SAE AMS 2644 and Pratt & Whitney approved

- Method: Method B, Method C, and Method D

3. Water-Based Fluorescent Penetrants

Best For: Environmental compliance, materials sensitive to petroleum products

ZL-4C

- Type: Water-based fluorescent penetrant

- Applications: Materials affected by petroleum-based penetrants, leak detection

- Features: Contains no petroleum derivatives, direct drain disposal possible

- Environmental Benefits: Reduced environmental impact

ZL-405 (Level 1/2)

- Type: Water-based, water washable

- Sensitivity: Level 1/2

- Features: No petroleum distillates, direct drain disposal

- Applications: Environmentally sensitive applications

ZL-425 (Level 1)

- Type: Water-based, water washable

- Sensitivity: Level 1

- Features: No petroleum distillates, direct drain disposal

- Applications: Basic inspections with environmental considerations

ZL-440 (Level 2)

- Type: Water-based, water washable

- Sensitivity: Level 2

- Features: No petroleum distillates, direct drain disposal

- Applications: Standard inspections with environmental compliance

4. Supporting Products

Developers

- ZP-4D: Dry powder developer (Form a)

- ZP-5B: Water suspendible developer (Form c)

- ZP-9F: Solvent-based developer (Form d/e)

- ZP-14A: Water soluble developer (Form b)

Emulsifiers

- ZE-4E: Lipophilic emulsifier (Method B)

- ZR-10E: Hydrophilic emulsifier (Method D)

Cleaners/Removers

- SKC-S: NDT cleaner and remover for pre-cleaning and excess penetrant removal

Industry Applications

Aerospace

- Recommended Products: ZL-27A, ZL-37, ZL-60D, ZL-67

- Applications: Aircraft components, engine parts, fasteners

- Requirements: High sensitivity, strict quality standards

Automotive

- Recommended Products: ZL-19, ZL-150, ZL-15B

- Applications: Engine blocks, transmission components, chassis parts

- Requirements: Production efficiency, reliable crack detection

Power Generation

- Recommended Products: ZL-27A, ZL-37, ZL-56

- Applications: Turbine components, pressure vessels, critical welds

- Requirements: Maximum sensitivity for safety-critical parts

General Manufacturing

- Recommended Products: ZL-19, ZL-150, ZL-405

- Applications: Machined components, castings, forgings

- Requirements: Cost-effective, reliable inspection

Medical/Surgical

- Recommended Products: ZL-4C, water-based penetrants

- Applications: Surgical implants, medical devices

- Requirements: Biocompatible, no petroleum residues

Selection Criteria

Sensitivity Level Requirements

- Level 1: Basic inspections, non-critical applications

- Level 1/2: Moderate sensitivity requirements

- Level 2: Standard industrial applications

- Level 3: High-sensitivity applications

- Level 4: Ultra-high sensitivity, critical safety components

Process Method Selection

- Method A (Water Washable): Fastest processing, easiest removal

- Method B (Post-Emulsifiable): Maximum process control, enhanced sensitivity

- Method C (Solvent Removable): Portable applications, field inspections

- Method D (Hydrophilic Emulsifiable): Enhanced process control with water-based removal

Environmental Considerations

- Standard Penetrants: Petroleum-based, established performance

- Water-Based Penetrants: Environmentally friendly, suitable for sensitive materials

Purchasing Considerations

Volume Requirements

- Low Volume: Aerosol containers, small kits

- Medium Volume: Gallon containers, bulk systems

- High Volume: Drum quantities, automated systems

Specification Compliance

- AMS 2644: Aerospace material specification

- ASTM E1417: Standard practice for liquid penetrant testing

- Pratt & Whitney: Specific aerospace approvals

Storage and Handling

- Shelf Life: Typically 2-3 years when properly stored

- Storage Temperature: Follow manufacturer guidelines

- Safety: Proper ventilation and PPE requirements

Conclusion

The Zyglo product line offers comprehensive solutions for fluorescent penetrant testing across diverse industries. Selection should be based on sensitivity requirements, processing method preferences, environmental considerations, and specific industry standards. For critical applications, consider post-emulsifiable penetrants with higher sensitivity levels, while water washable penetrants offer efficiency for high-volume production environments.