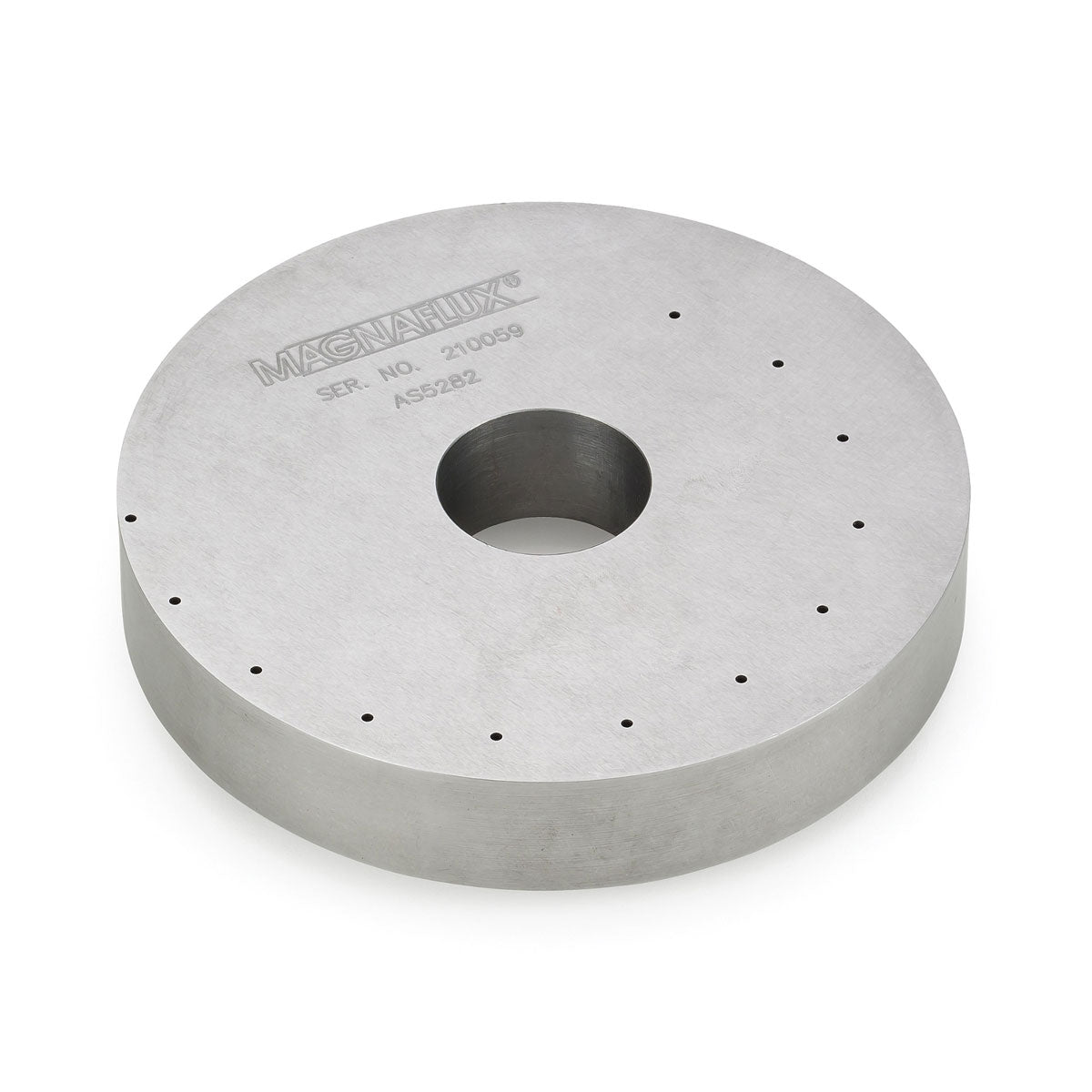

Magnaflux Tool Steel Test Ring

The Tool Steel Ring is a standardized test piece commonly used with wet bench magnetic particle equipment. The ring is machined from AISI O1 Tool Steel, annealed, tested and certified to meet AS 5282 specifications. Typically used with a 1 inch central conductor, the Tool Steel Ring has 12 machined holes at increasing depths from the edge and is used to verify the performance of HWDC, FWDC, and 3-phase FWDC magnetizing equipment. Suitable for use with wet or dry materials and visible or fluorescent particles. The number of indications required depends on the waveform and magnetizing current amperage (refer to AS 5282 or ASTM E1444 for more information).

Dimensions

- Outer Diameter - 5.00 in / 127.0 mm

- Inner Diameter - 1.25 in / 31.8 mm

- Thickness - 0.88 in / 22.2 mm

Manufactured and annealed to AS 5282 specifications.

Precision-machined subsurface defects

- 0.07 in / 1.78 mm

- 0.14 in / 3.56 mm

- 0.21 in / 5.33 mm

- 0.28 in / 7.11 mm

- 0.35 in / 8.89 mm

- 0.42 in / 10.67 mm

- 0.49 in / 12.45 mm

- 0.56 in / 14.22 mm

- 0.63 in / 16.00 mm

- 0.70 in / 17.78 mm

- 0.77 in / 19.56 mm

- 0.84 in / 21.34 mm