-

Magnaflux Magnetic Flux Indicators

Regular price $286.00Regular priceUnit price per -

Standard QQI-Model CX-230 - 5 per package

Regular price $331.00Regular priceUnit price per -

Magnaflux Standard QQI-Model CX-430 - 5 per package

Regular price $518.00Regular priceUnit price per -

Magnaflux QQI Model CX4-230 - 5 per package

Regular price $550.00Regular priceUnit price per -

Magnaflux Tool Steel Test Ring - Certified

Regular price $909.00Regular priceUnit price per -

Magnaflux MPI Test Bar

Regular price $960.00Regular priceUnit price per

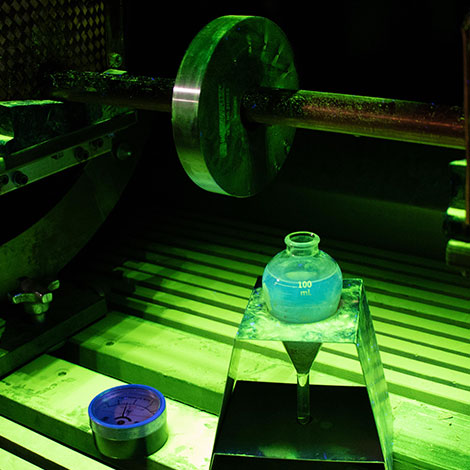

Magnaflux Magnetic Particle Test Pieces

Overview

Magnaflux magnetic particle test pieces are designed to help maintain magnetic particle inspection processes by verifying magnetic particle performance. They serve multiple purposes including checking for particle deterioration, comparing different magnetic powders, verifying sensitivity or visibility, and assuring proper field direction and strength.

Product Categories

1. Magnetic Flux Indicators

- Design: Flexible indicators for detecting directional orientation during magnetic particle testing

- Construction: Made from permeable magnetic steel sandwiched between two brass plates

-

Specifications: Contains three milled slots with precise widths:

- 0.0075 inches

- 0.009 inches

- 0.010 inches

- Features: All slots share a common depth and are designed for repeated use

- Applications: Suitable for both wet and dry MPI applications for setting and monitoring magnetic field strength

2. Quantitative Quality Indicators (QQI)

QQI test piece shims feature artificial defects to verify field direction and relative strength. They're packaged in sets of five and available in multiple configurations:

| Part Number | Product Name | Description |

|---|---|---|

| 631590 | CX-230 | Thickness: 0.002 inch (0.05 mm) Notch flaw depth: 30% of shim thickness |

| 631591 | CX-430 | Thickness: 0.004 inch (0.10 mm) Notch flaw depth: 30% of shim thickness |

| 631592 | CX4-230 | Features four circle-cross notch patterns User cuts into four separate shims Thickness: 0.002 inch (0.05 mm) Notch flaw depth: 30% of shim thickness |

Key Benefits: QQIs help balance multi-directional fields and increase productivity by minimizing magnetizing shots.

3. Tool Steel Ring (AS-5282)

- Former Name: Previously known as Ketos Ring

- Design: Pre-drilled holes simulate subsurface discontinuities

- Purpose: Provides reliable verification of magnetic particle system performance

- Use Case: Ideal when actual test parts with discontinuities are not available

4. Magnetic Particle Test Bar

- Defect Types: Contains both coarse and fine surface and subsurface defects

- Directionality: Defects oriented in both directions

- Standards Compliance: Meets or exceeds most industrial and military standards for artificial test specimens

Conclusion

These test pieces collectively provide comprehensive solutions for validating magnetic particle inspection systems across various industrial applications and standards requirements.