Why Visible Dye Penetrant Testing is Essential for Non-Destructive Inspections

Share

In the realm of quality control and assurance, the significance of visible dye penetrant testing cannot be understated. This crucial non-destructive testing (NDT) method is employed widely across various industries, including aerospace, automotive, and manufacturing. By identifying surface-breaking defects such as cracks and porosity, visible dye penetrant testing helps to ensure the integrity and safety of components without compromising their usability.

What is Visible Dye Penetrant Testing?

Visible dye penetrant testing involves applying a liquid dye solution to the surface of a material. This dye enters any surface discontinuities present in the material, such as flaws or cracks. After a specific dwell time, excess dye is removed, and a developer is applied. This developer draws the dye out of the defects, creating a visible indication that can be easily seen. The entire process is relatively simple yet requires meticulous attention to detail and adherence to standards.

How Does Visible Dye Penetrant Testing Work?

The process of visible dye penetrant testing typically follows several key steps:

- Surface Cleaning: Before application, the surface must be thoroughly cleaned to remove contaminants that could interfere with the dye's capability to enter defects.

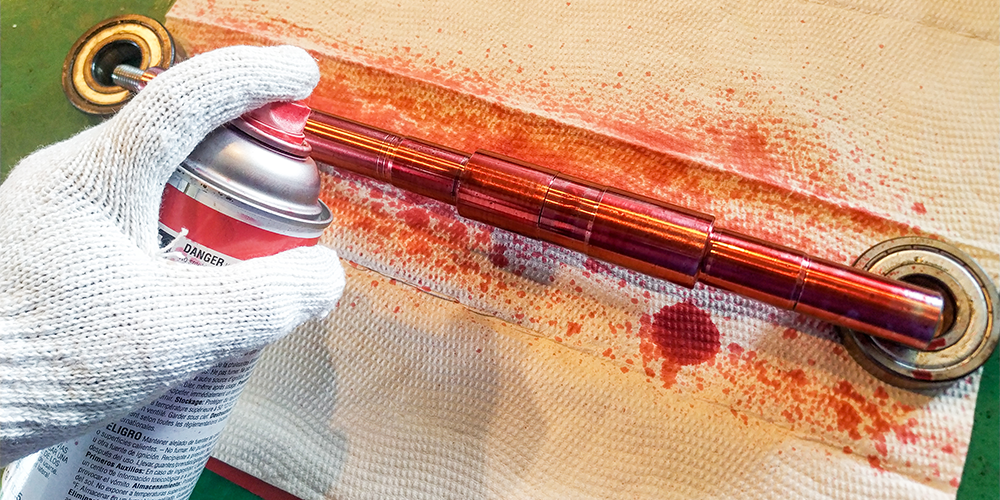

- Dye Application: A colored dye penetrant is applied to the surface, allowing it to seep into any cracks or flaws.

- Dwell Time: The penetrant needs to dwell on the surface for a designated period, which allows it to infiltrate the defects adequately.

- Excess Penetrant Removal: After the dwell time, excess penetrant is wiped off the surface carefully, ensuring that only the penetrant in the defects remains.

- Developer Application: A developer is then applied, which acts like a blotter, drawing out the trapped dye from the defects and creating an easily visible indication.

- Inspection: The final inspection is performed under suitable lighting conditions to assess the indications and determine the presence of defects.

Advantages of Visible Dye Penetrant Testing

There are multiple advantages to using visible dye penetrant testing:

- Non-Destructive: As a non-destructive testing method, visible dye penetrant testing does not damage the material being examined, making it ideal for critical components.

- Cost-Effective: This method is generally less expensive than other NDT methods such as ultrasonic testing or radiography, making it accessible for many organizations.

- Quick Results: The process is relatively fast, allowing for rapid identification of defects in production lines and quality assurance processes.

- High Sensitivity: Visible dye penetrant testing can detect very fine cracks and surface irregularities, contributing to the overall safety and reliability of the product.

- Versatile Application: It can be used on various materials, including metals, plastics, and ceramics, making it a flexible testing solution.

Applications of Visible Dye Penetrant Testing

Visible dye penetrant testing is an essential tool in several industries, each using it to ensure the safety and efficacy of their products:

- Aerospace: Used to inspect critical components like landing gear and airframes where the integrity of flight parts is paramount.

- Automotive: Manufacturers utilize this testing to ensure safety in components like engine blocks and suspension systems.

- Oil & Gas: It is used for inspecting pipelines and tanks to prevent leaks and ensure safety in operations.

- Manufacturing: It is applied for everyday components to ensure that they meet stringent safety standards.

Common Standards & Guidelines

Many industry standards govern visible dye penetrant testing, ensuring that organizations use appropriate testing protocols. Some of the notable standards include:

- ASTM E165: This standard outlines the guidelines for liquid penetrant testing.

- ISO 3452: This standard provides specific requirements for the non-destructive testing of materials.

- API 510: Developed for pressure vessels, this standard provides guidelines for visible dye penetrant testing and other inspection methods.

Conclusion

Visible dye penetrant testing plays a vital role in the field of non-destructive inspections. Its ability to detect surface flaws quickly and reliably ensures enhanced quality control in various sectors. By adopting this method, companies can improve their safety standards and product reliability, ultimately saving costs associated with failures or recalls. Understanding the benefits, principles, and applications of visible dye penetrant testing is essential, as it is a fundamental practice in ensuring product integrity and operational excellence.